| Sign In | Join Free | My chinaqualitycrafts.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinaqualitycrafts.com |

|

Brand Name : XWH

Model Number : DN(B)-160, DN(B)-200, DN(B)-250

Certification : CE

Place of Origin : China

MOQ : 1

Price : USD30000-USD40000

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 500 sets/month

Delivery Time : 15 working days

Packaging Details : Wooden Case

Product name : Multi Spot Welding Machine

Application : Welding Machine For Fuel Tank

Function : Projection Weldinng

Machine type : Manual Welding

Keyword : Multi-Spot Welding Machine

Welding Material : Alloy Metal Aluminum Stainless Steel

Feature : Projection Spot Welding

Warranty : 1 year Guarantee

After Warranty Service : Video technical support, Online support and Spare parts

After-sales Service Provided : Free spare parts, Field installation, commissioning and training

Multi-Electrode Resistance Multi-Point Fuel Tank Multi Point Spot Welding Machine

Product Introduction:

The welding principle of the 14 point fuel tank welding machine: By pressing the start button, 14 points in a circular layout can be welded in sequence. The 14 points can be divided into 1-14 steps (which can be set arbitrarily). The number of welding points in each step can be set arbitrarily, and the set parameter numbers such as current and time for each step can be matched and set arbitrarily; The factory default setting is to weld 2 points per step, and weld 14 points in 7 steps at once. Then, raise the upper electrode.

Advantages:

1. The overall structure has a unique style and is commonly used in welding operations of automotive fuel tanks. The body is designed for impact resistance, seismic resistance, and high rigidity, and is finely processed by machinery to meet the installation and load strength of various components. Multiple reinforcement ribs have been welded inside the frame to ensure the rigidity of the equipment and minimal deformation during the welding process, ensuring the stability of welding and the safety of manual use.

2. The upper electrode is pressurized by an auxiliary cylinder, which makes stroke adjustment convenient and accurate, making the workpiece operation stroke continuously adjustable.

3. The spare dedicated gas storage tank for welding machines is beneficial for reducing welding pressure fluctuations and ensuring stable welding force.

Technical Parameters:

| Models/Item | DN(B)-100 | D(N)B--160 | D(N)B--200 | D(N)B--250 |

| Rated power (KVA) | 100 | 160 | 200 | 250 |

| Power input(V) | 3φAC 380V | 3φAC 380V | 3φAC 380V | 3φAC 380V |

| Max. short circuit current(KA) | 30 | 40 | 40 | 45 |

| Max. force (N) | 6000 | 6000 | 10000 | 15000 |

| Electrode length(MM) | 450 | 450 | 450 | 500 |

| Working stroke(MM) | 80 | 80 | 80 | 80 |

| Cooling consumption(L/min) | 20 | 20 | 20 | 20 |

| Max.welding capacity(MM) | 3.0+3.0 | 4.0+4.0 | 5.0+5.0 | 6.0+6.0 |

General Structures:

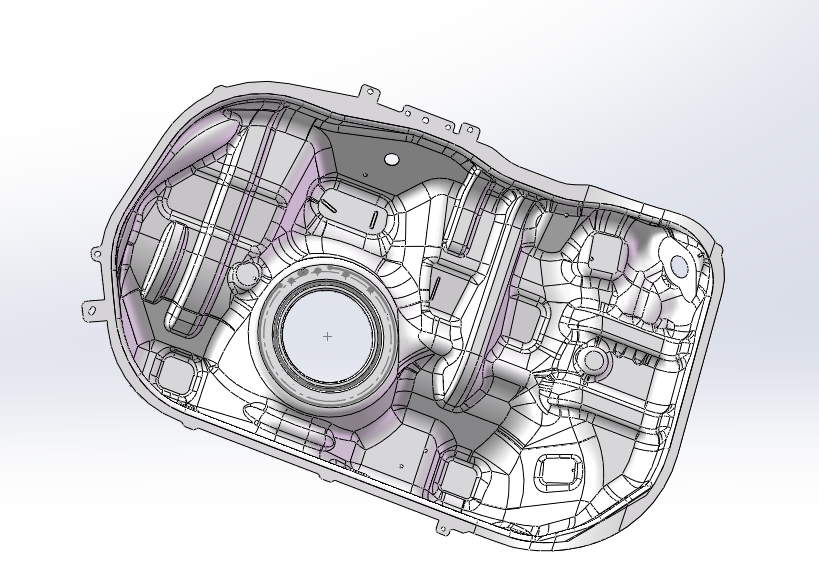

Workpiece:

Production Line:

Application:

FAQ:

|

|

Multi-Electrode Resistance Multi-Point Fuel Tank Multi Point Spot Welding Machine Images |